Unfold Form

8093 Zürich,

Suisse

Publié le 18 juillet 2025

ETH Zürich - Institute of Technology in Architecture BLOCK Research Group

Participation au Swiss Arc Award 2025

Données du projet

Données de base

Données du bâtiment selon SIA 416

Description

The project was developed during the 2024–2025 academic year. It was conducted within the Block Research Group, under the direction of Prof. Dr. Philippe Block. The participating students were Lotte Scheder-Bieschin and Mark Hellrich.

Introduction

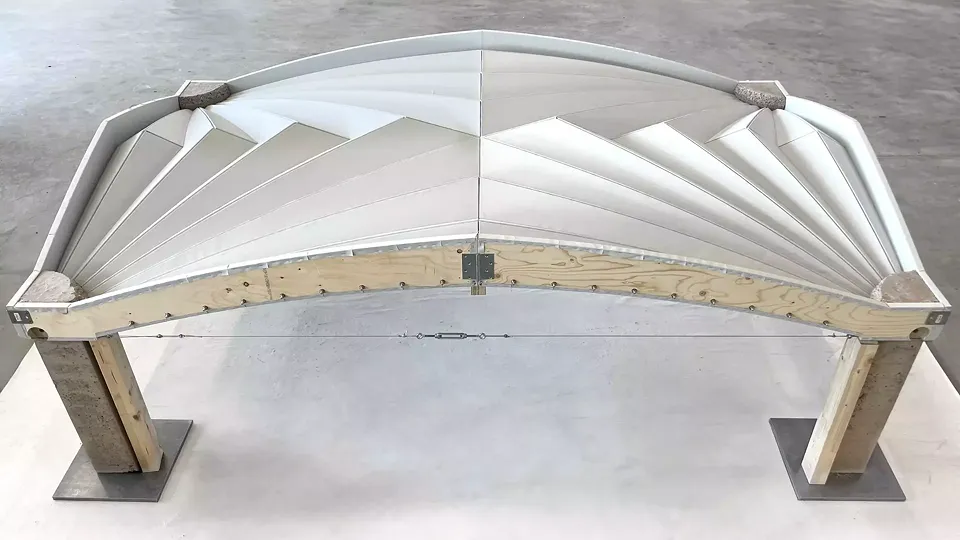

Unfold Form is the first-ever construction system to use curved-crease unfolding as the deployment and shaping mechanism of formworks for sustainable vaulted floors in unreinforced concrete. Bending-active plates connected with curved textile hinges, weighing only 24 kilograms, unfold on-site into a self-supporting formwork able to support 1000 kilograms of concrete. Unfold Form offers a robust, lightweight, reusable alternative to traditional formworks. It combines low-tech construction practices with sophisticated structural geometry, making it a groundbreaking solution for reducing carbon emissions and material waste.

Corrugated Fan Vaults

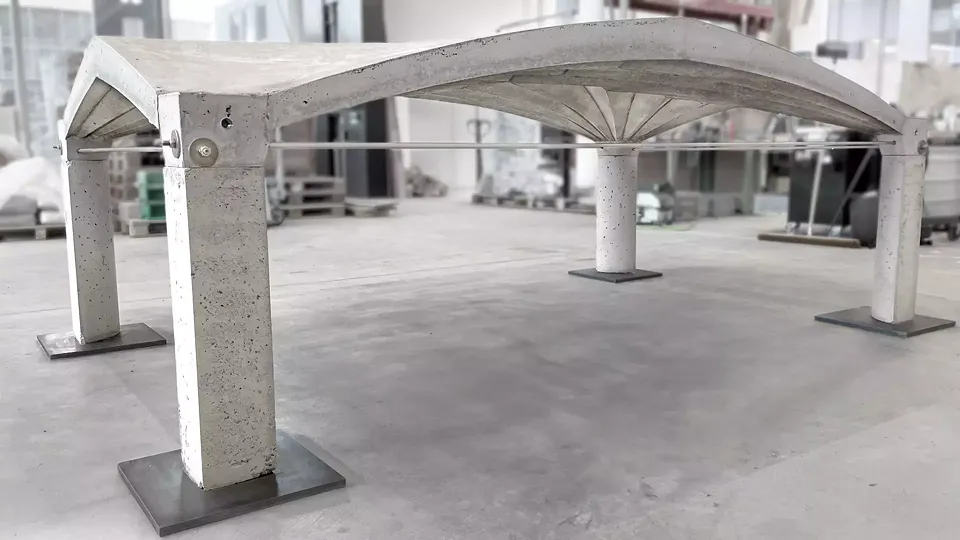

Vaulted, unreinforced concrete floors derive strength from their specific geometry, allowing them to carry loads efficiently and mostly in compression. By significantly reducing the amount of concrete required compared to traditional flat slabs, and eliminating the need for embedded reinforcement steel, these funicular floors contribute to the reduction of carbon emissions associated with the construction of buildings, and promote circular construction.

Following this principle of «Strength Through Geometry» and inspired by historic Gothic construction, Unfold Form uses a corrugated fan vault as the base structural typology for the development of a sustainable floor system, with an innovative formwork.

Unfoldable Bending-active Formwork

Formworks for non-standard, curved geometries are typically costly, wasteful, bulky, often single-used, and frequently rely on digital fabrication, which is not commonly available in developing contexts where the demand for new construction is highest.

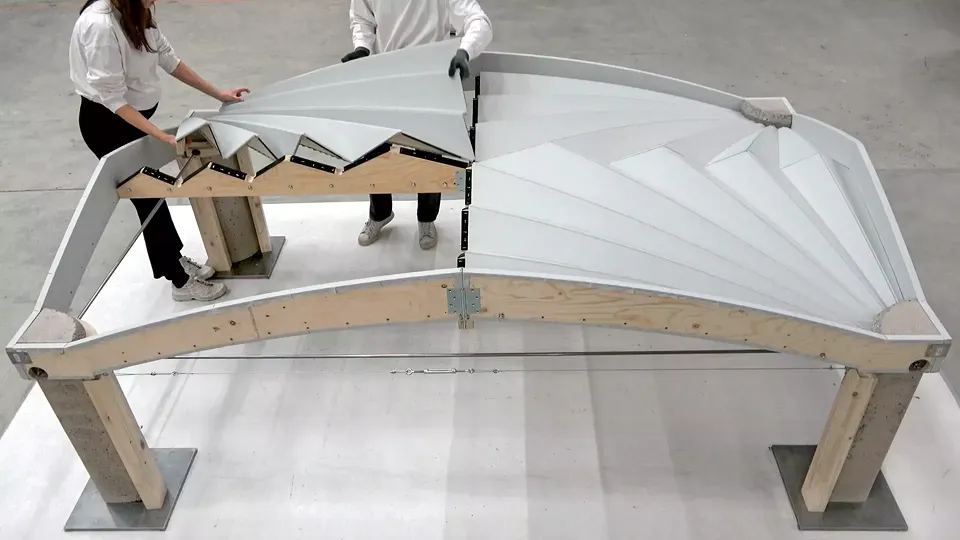

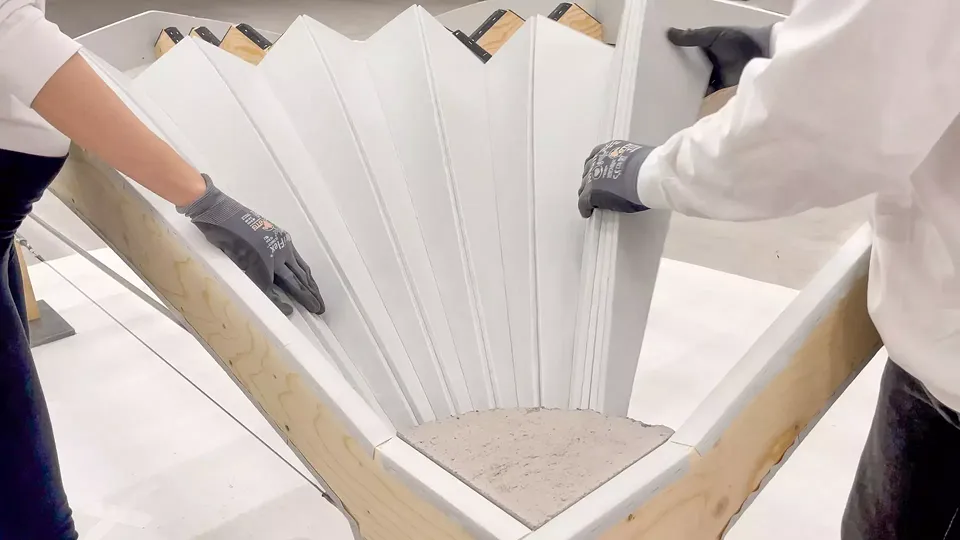

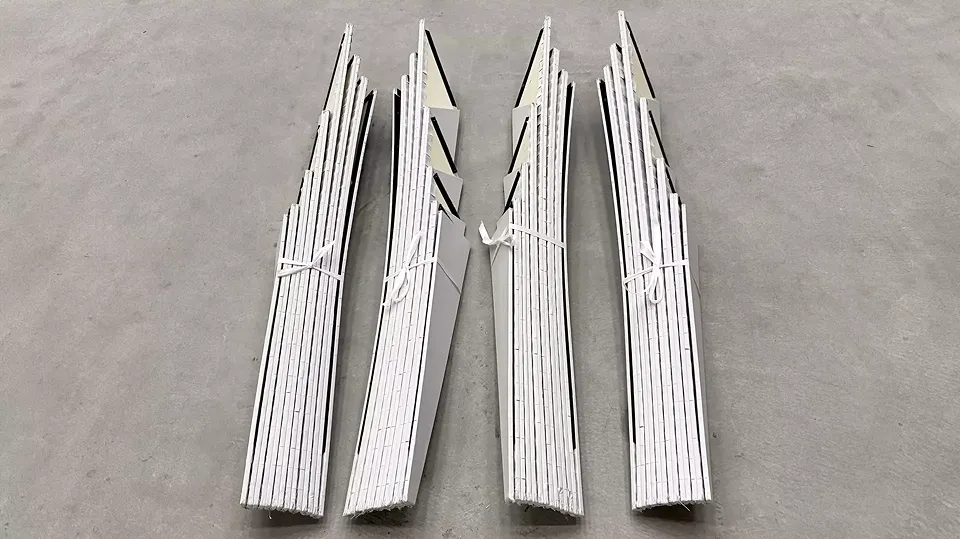

Instead, Unfold Form provides a formwork solution that, as for the resulting structure, bases its strength on geometry. Additionally, its controlled shape results from the geometric principles of curved crease unfolding: It is made from curved-creased, bending-active plates that unfold fan-like into a material-efficient, self-supporting, corrugated formwork. Its curved creases control the funicular shape, while its corrugations provide the necessary stiffness to the thin formwork. The latter translates into the concrete rib articulations that enhance the material efficiency of the floor structure.

This innovative system offers low-tech, low-cost prefabrication, flat-packed, lightweight transport, and rapid, on-site deployment into a robust, reusable formwork for constructing sustainable vaulted floors. It is not dependent on high-tech fabrication facilities and skilled labour, so it is globally applicable, drastically increasing its potential impact on more sustainable construction practices worldwide.

Curved-Crease Unfolding

Curved-crease unfolding (CCU) is a new extension to curved-crease folding (CCF) recently introduced by Scheder-Bieschin. While CCF is folded from a large surface, impractical for transport, in CCU, instead, flat-folded, bending-active plates, compact for transport, are unfolded in a fan-like manner into a double-curved, corrugated structure. Materialised with bending active plates joined along curved textile hinges, the curved crease folding is taken beyond its typical realm of installations to serve as formwork for the construction of vaulted floors.

Hi-tech design, low-tech fabrication

The Unfold Form construction system was designed using an integrative computational co-design process that allows optimising for reciprocal geometric, structural, and fabrication constraints for both the formwork and shell structure.

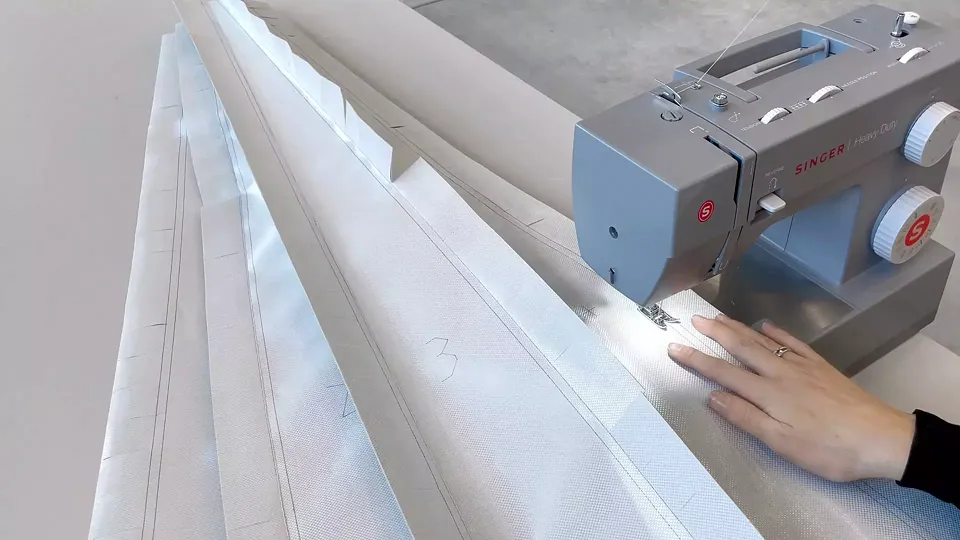

However, as the intelligence is embedded in the geometric principles of curved-crease unfolding, its fabrication is low-tech, low-cost, and straightforward. A PVC-coated polyester textile is tailored along the crease pattern and joined with flat 8 millimetres thick plywood plates. The material costs amount to only 650 CHF. On-site, the kit of parts can be rapidly assembled and deployed in a plug-and-play manner within half an hour only, with high geometric precision. This simplicity of fabrication fosters the inclusion of gender-equitable, local, untrained labour.

Proof of Concept

Two half-scale prototypes, one in Zurich and one in Cape Town, have successfully demonstrated the potential structural, logistical and environmental benefits of the Unfold Form system. Weighing just 24 kilograms and measuring 160 x 40 x 25 centimetres, the compact flat-packed formwork was easily transported as checked luggage by plane from Switzerland to South Africa. Its reusability across multiple casting cycles, without losing quality, underscores its potential to reduce waste significantly.

The resulting concrete shell, spanning 3 meter by 1.8 meter, weighs 1000 kilograms and is 5 centimetres at its thinnest and 13 centimetre at its thickest. Following conventional practices, the floor system is completed with a circular fill to provide a flat top. The corrugations provide structural height for live loads and a fascinating architectural expression, not despite but because of the constraints of structural efficiency and fabrication economy.

Outlook

Unfold Form can be applied in both high-tech and low-tech contexts, due to its aesthetics, efficiency and low-tech fabrication. As a direct outlook, we are collaborating with NonCrete, who developed a bio-concrete based on chipped alien invasive vegetation, on the development of sustainable floor solutions for low-cost, dignified housing in Cape Town, South Africa. By employing structural geometry for both formwork and resulting shell floor as opposed to wasteful moulds and inefficient slabs, the Unfold Form system offers a visionary approach to reduce the environmental impact of the construction industry.

- Weight: 24 kilograms

- Packed dimensions: 160 x 40 x 25 centimetres

- Material: 8 millimetres plywood, PVC-coated polyester fabric

- Costs: 650 CHF

- Assembly time: 30 minutes

Resulting floor system

- Spans/Dimensions: 3 meter x 1.8 meter (at half-scale)

- Shell thickness: 5–13 centimetres

- Total thickness: 40 centimetres (corners) – 10 centimetres (centre)

- Weight of concrete shell: 1000 kilograms

- Weight of stell: 10 kilograms

The project by the ETH Zurich Institute of Technology in Architecture Block Research Group was submitted for the Swiss Arc Award 2025 in the Next Generation category and published by Nina Farhumand.